Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

China Cnc Hardware Parts Metal Processing Machinery Manufacturers

-

0.00 ~ 0.00/

100/ (Min. Order)

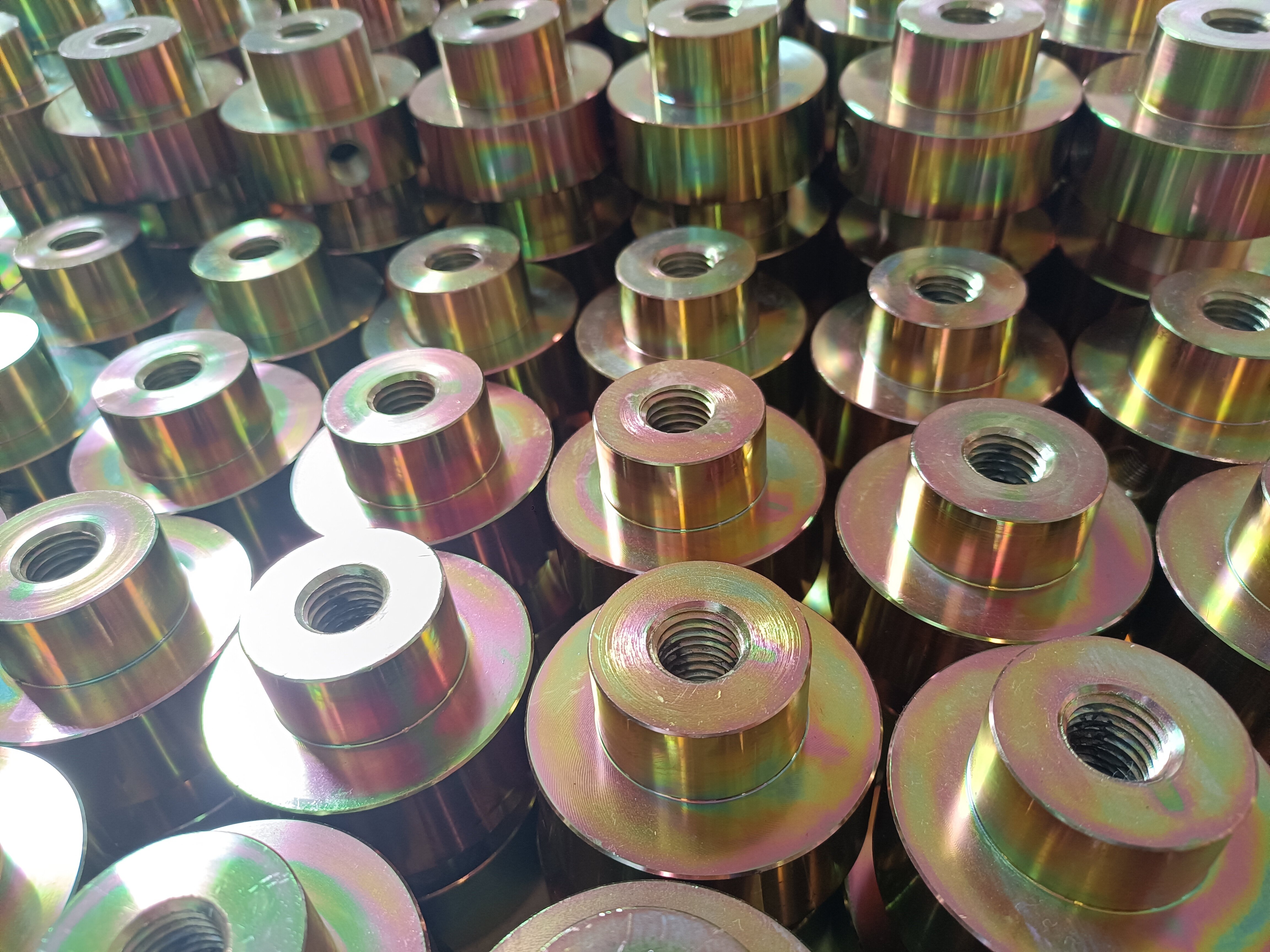

The CNC processing parts are meticulously crafted using top-grade materials, guaranteeing exceptional resistance to rust and corrosion. We prioritize every detail, and our state-of-the-art technology ensures precise and clean cutting edges. The surface finish of our parts is impeccably smooth and brilliantly bright, showcasing the abundance of high-quality materials employed in their manufacturing.

CNC Processing Parts Feature - China Hardware Parts Processing

High Precision: CNC processing parts are renowned for their exceptional productivity and efficiency, thanks to the utilization of automated processes. Once the program is set up, the machine can operate continuously, minimizing the requirement for manual intervention and significantly enhancing overall production output.

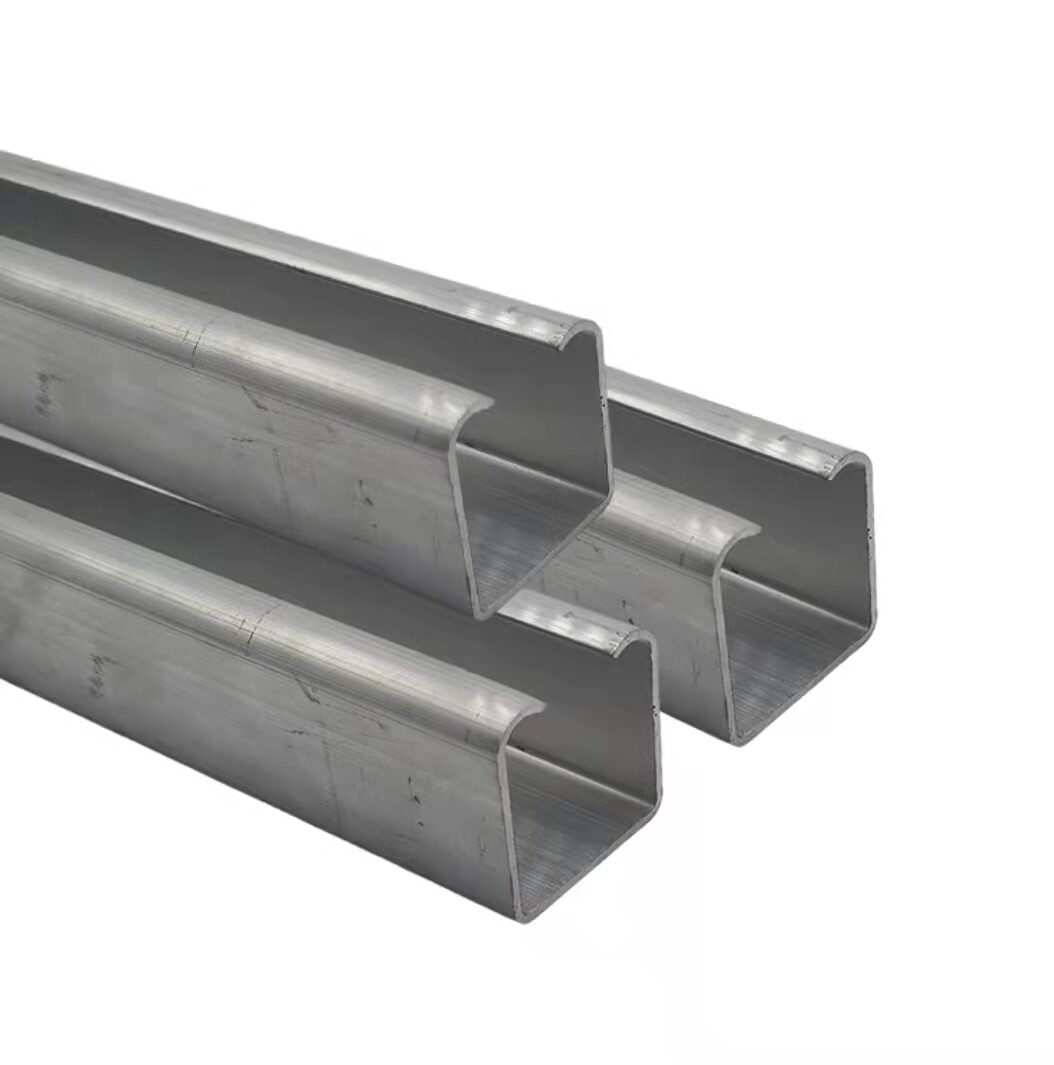

Multiple Material Options: CNC processing parts are incredibly versatile, as they can be used with a wide range of materials, including steel, aluminum, and more. This compatibility makes them highly suitable for diverse industries and applications.

CNC Processing Parts Advantages - China Hardware Parts Processing

Multiple Surface Finish Options: CNC machines excel at achieving exceptional surface finishes, often eliminating the need for additional finishing operations. The precision and accuracy of CNC machining processes result in smooth and flawless surfaces on the manufactured parts. This high-quality surface finish not only enhances the aesthetics of the parts but also eliminates the requirement for time-consuming and costly post-processing steps.

Various Customization to Meet Specific Requirement: CNC parts offer exceptional customization capabilities, allowing for quick and precise adjustments according to specific requirements. With CNC programming, changes in design or dimensions can be easily implemented, enabling rapid modifications to the manufacturing process. This flexibility ensures that CNC parts can be tailored to meet unique specifications, whether it’s altering the shape, size, or features of the component.

Application of CNC Processing Parts - China Hardware Parts Processing

- Automotive Industry: such as engine parts, transmission parts, chassis components, and interior/exterior trim pieces;

- Aerospace Industry: Including turbine blades, aircraft frames, structural components, and landing gear;

- Medical Industry: Such as surgical instruments, prosthetics, dental implants, and orthopedic implants;

- Electronics Industry: Such as printed circuit boards (PCBs), connectors, heat sinks, and enclosures;

- Defense Industry: For the manufacturing of military equipment, weapons systems, armored vehicles, and communication devices;

- Energy Sector: Including turbine parts, valve bodies, generators, and heat exchangers;

- Industrial Machinery: Such as heavy-duty equipment, industrial robots, CNC milling machines, and machining centers;

- Consumer Goods Industry: Like kitchen appliances, electronic gadgets, furniture, and sporting goods;

- Tool and Die Industry: In the production of precision molds, dies, and cutting tools required for various manufacturing processes;

- Architectural and Construction Industry: To fabricate architectural components, facade elements, structural supports, and decorative pieces for buildings and structures.